Insider - September 2016

First tool in Spec with Wheel check Module

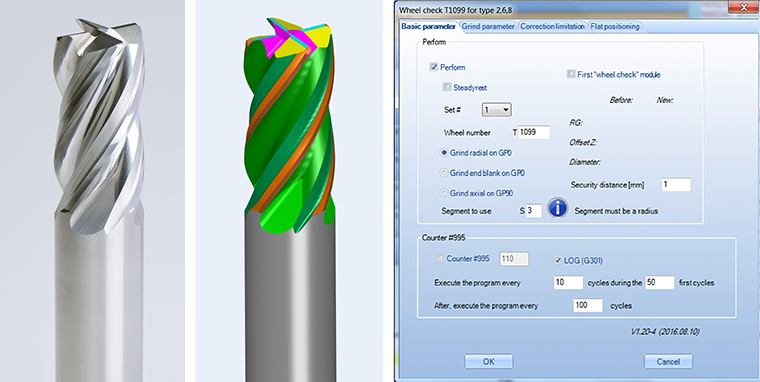

In-process wheel measurement "Wheel check"

To help customers cut-down their setup times, we developed the new feature "WheelCheck". Here, the measuring process occurs just before grinding the first workpiece. The imprints generated by the grinding wheel in the unfinished blank help to determine the exact positions and radii of each grinding wheel. This process is done on the same blank that will be used for grinding the tool. With WheelCheck, tests show setup is shortened by about 50% from the mechanical adjustment to the start of tool production.

Example of application : Ø 5.95 mm 4 teeth endmill, core Ø 3.87 mm and web thickness 0.27mm

New VirtualGrind®Pro feature

With the new operation panel integrated directly in the 3D tool window you can select which operation you would like to simulate. It works by simply tagging the operations you wish to simulate. This new feature will help you save precious programming time, since all the information needed is gathered on the same page. The new tree structure also means that complete operations can be activated or deactivate with a single click.