Insider - February 2017

This email address is being protected from spambots. You need JavaScript enabled to view it.

Dynamic runout compensation

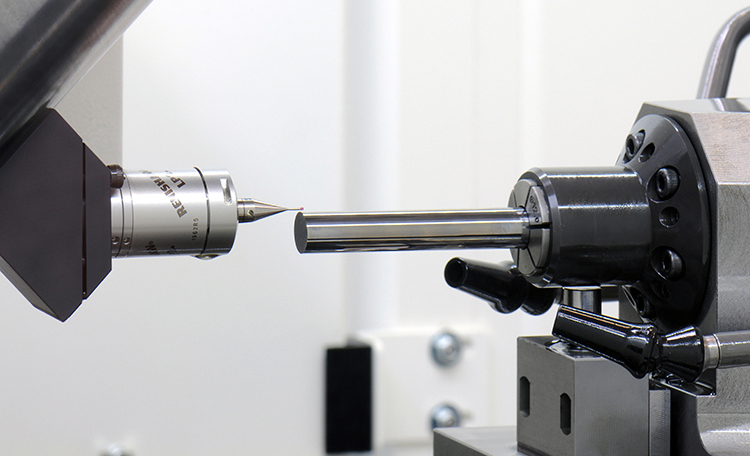

The production of small batches requires short, accurate and efficient setups and it is with this goal in mind that the dynamic runout compensation module has been developed. Thanks to this new functionality, the centering shank guide system as well as the steady rest are no longer required, since the potential errors of runout are measured by the touch probe and then dynamically compensated during the grinding process. This module allows compensating any kind of endmill ranging from Ø 3.0 to Ø 20.0 mm.

THE BENEFITS OF THE DYNAMIC RUNOUT COMPENSATION :

- Reduce setup times. Ideal for small batches.

- Allows grinding tools by keeping runout within 0.005 mm without use of shank guide or steady-rest.

OD grinding with cup wheel

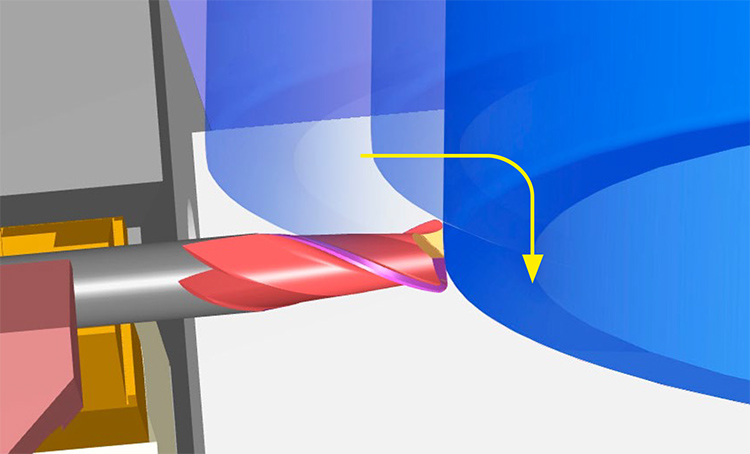

Rollomatic grinders traditionally used peripheral wheel for the relieving of ball and corner radius endmills. Starting from VirtualGrind®Pro 1.20, a cup wheel can be used as alternative grinding method for this operation. The use of cup a wheel provides several advantages, one of which is obtaining a more flat relief shape. Another unique feature of the Rollomatic 6-axes machines regarding this operation is the ability to incline the A-axis in order to minimize the need to continually walk the wheel grinding point during radius grinding, and therefore be able to produce a more accurate ball shape.

BENEFITS OF GRINDING OD WITH A CUP WHEEL :

- Possibility to have flat relief shape.

- Displacement of the grinding contact point can be minimized on 6-axis grinders resulting with enhanced accuracy on radii and ball shapes.