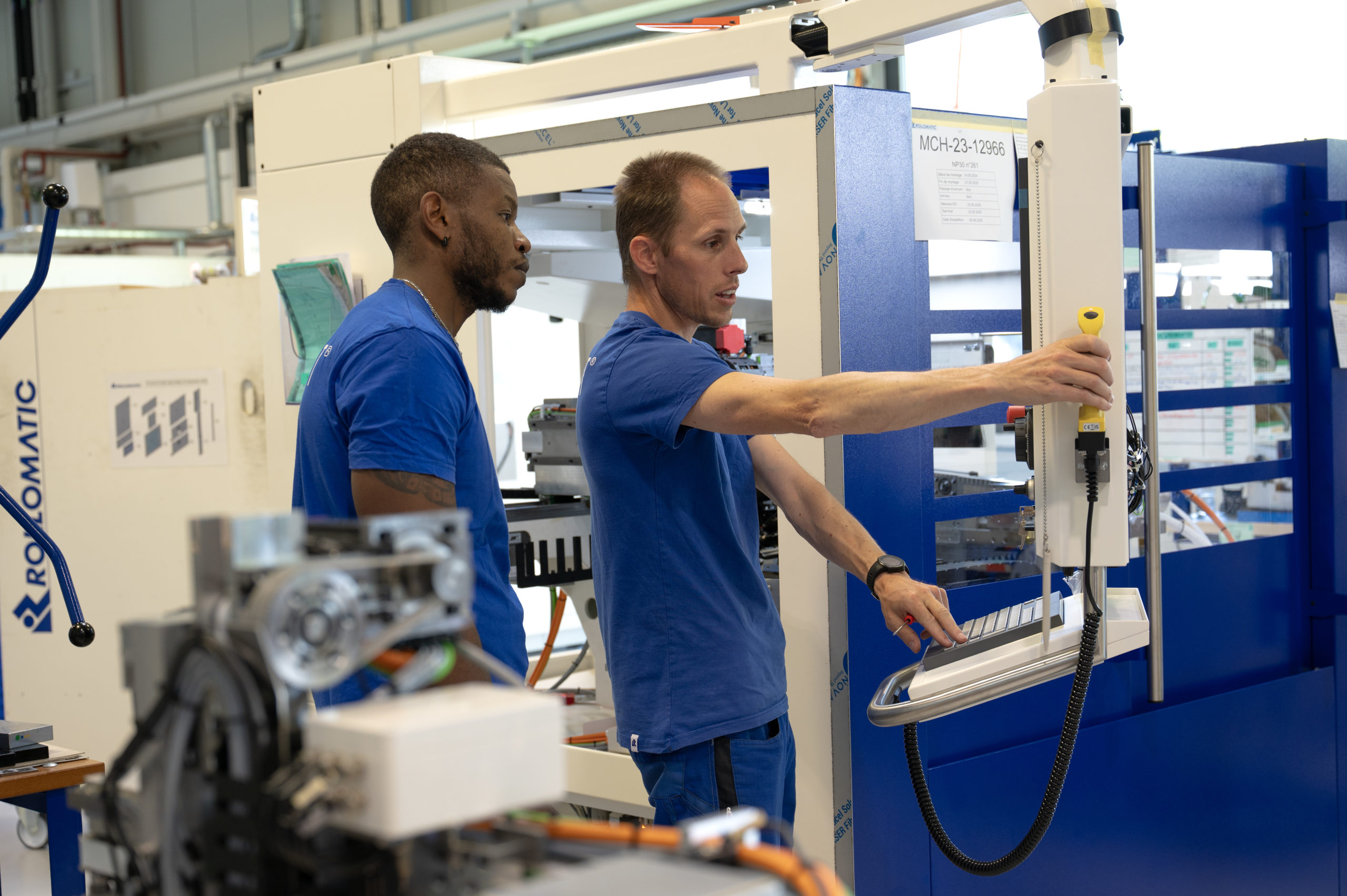

PRODUCTION

Dive into the heart of Rollomatic, where innovation comes alive. With 5 assembly lines optimized according to Lean principles, a production capacity of 700 machines per year, and a modern, organized, and technological workplace, we produce cutting-edge solutions for various industries (medical, dental, aerospace, watchmaking, automotive, electronics, etc.) and radiating globally.