LaserSmart® 510

The LaserSmart 510 has been designed to allow for faster cutting speeds of up to 450% over conventional laser machining.

The laser machining process used on this machine is infinitely superior to any other traditional method of machining super-hard materials such as PCD, CVD diamond, monocrystalline diamond, natural diamond and PCBN.

Advantages

Unique laser process creates razor-sharp cutting edges with a radius of less than 1µm

The machining process is independently offset on the raw brazed PCD material

Surface finish quality well above industry standards

Cylindrical margins are machined all within a single clamping

Automation solutions for interchangeable inserts, HSK63 station, and round shaft

Smart features

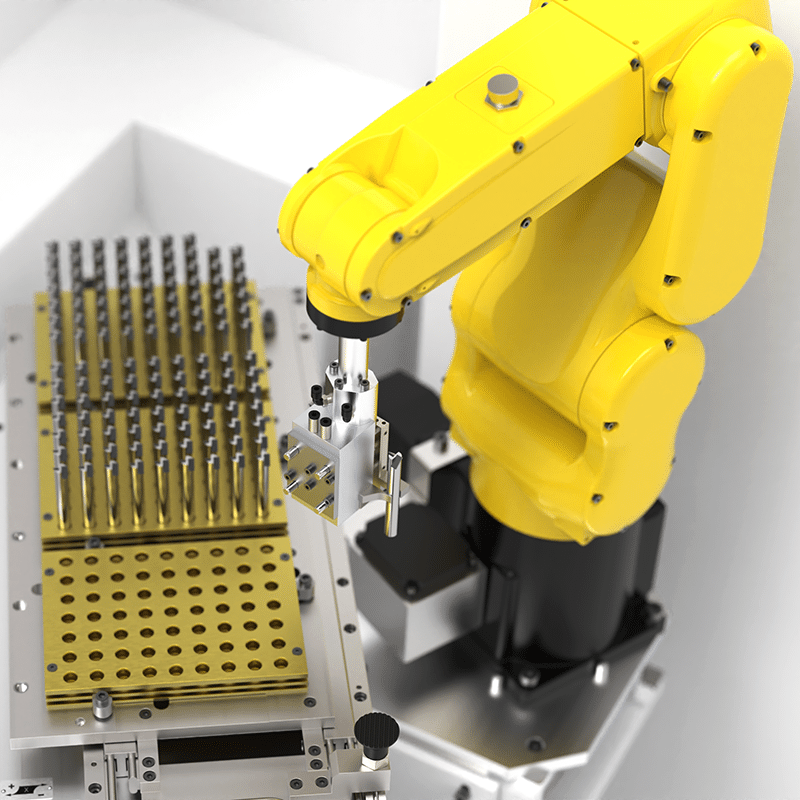

Smart Tool Loader

The high-speed tool loader, designed by Rollomatic and integrated into the basic machine, was developed with fast setup and ease-of-use in mind.

This is achieved by using pre-calibrated cassettes and clamps to hold different diameters without resetting the position. Rollomatic automatic loaders are known to be the fastest and most reliable in our industry.

- Fast to set up

- Capacity up to 1’000 parts

- Robust, low maintenance design

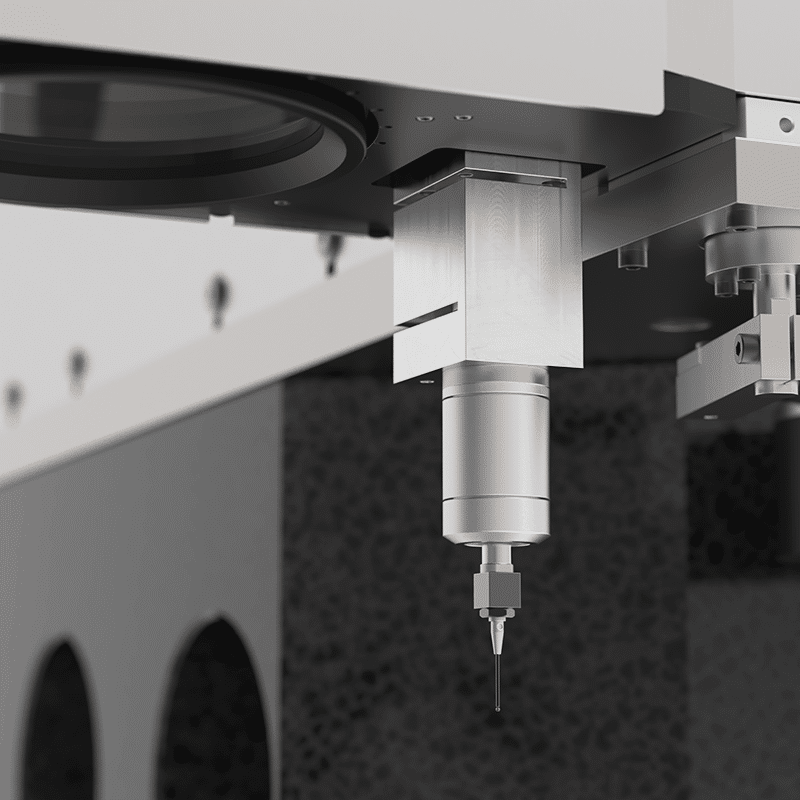

Smart Touch Probe

The Smart Touch Probe is a contact measurement system that allows the blank position to be defined before grinding and avoids variations during production. The system also compensates for machine thermal drift caused by changes in ambient temperature.- Runout compensation and core diameter measurement

- Setting assistance

- Superior stability during the production process

- Elimination of scrap during unattended production

Software

LaserSuite

Based on a new easy-to-use, graphical interface, the software provided with the LaserSuite offers simulated 3D operations and allows the user to inspect the laser beam trajectory and to optimize the cycle time before production to ensure zero scrap, all while offline. The Rollomatic JobManager program allows various types of tools to be uploaded on the machine’s control and allows for Unattended Production Learn moreSmart Connectivity

Industry 4.0 is a constantly evolving world, and management tools have been developed to optimise its productivity. Rollomatic strives to develop connectivity solutions that are compliant with the UMATI standard, facilitating connections between peripherals in production processes and leveraging the available data

Learn moreFor Rollomatic, the process is as important as the machine. To better serve our customers, we are able to provide full turnkeys with every machine.

Turnkey

The turnkey process starts with our Sales Team and their help in defining your project.

Our expert team of Applications Engineers then studies your parts to determine the best machine, options, accessories, peripheral equipment, programs, and training required.

We can also offer Factory Acceptance and Site Acceptance Tests to ensure confidence in the machine and process.

Oil Filtration Systems

Mist Collectors

Balancing Machines

Wheel Presetting Machines

Programming

In Person & Virtual Training

Wheel Dressing & Truing Machines

Grinding Oils

Grinding Wheels

Metrology Equipment

We welcome the opportunity to be a part of your success!